What is the real definition of High-Performance Etching And Deposition Solutions: Riber's Leading-Edge Technologies For Advanced Semiconductor Manufacturing? Riber is a global expert in molecular beam epitaxy (MBE) and a market leader in thin film deposition technologies.

Editor's Notes: High-Performance Etching And Deposition Solutions: Riber's Leading-Edge Technologies For Advanced Semiconductor Manufacturing have published on 3rd Jan 2023. This topic is important to understand How Riber's leading-edge technologies play a critical role in advanced semiconductor manufacturing.

After doing some analysis, digging information, made High-Performance Etching And Deposition Solutions: Riber's Leading-Edge Technologies For Advanced Semiconductor Manufacturing we put together this High-Performance Etching And Deposition Solutions: Riber's Leading-Edge Technologies For Advanced Semiconductor Manufacturing guide to help target audience make the right decision.

Key differences or Key takeways, provide in informative table format

| MBE Systems | CVD Systems | |

|---|---|---|

| Applications | Advanced semiconductor materials research and development, production of high-performance electronic and optoelectronic devices | Production of high-quality dielectric and metal films for advanced semiconductor devices |

| Technology | Molecular beam epitaxy (MBE) | Chemical vapor deposition (CVD) |

| Advantages | Precise control of film growth, high-quality materials, low defect densities | High throughput, excellent film uniformity, low particle contamination |

Transition to main article topics

FAQ

This FAQ section addresses frequently asked questions regarding Riber's high-performance etching and deposition solutions.

![]()

IDTechEx Explores Materials and Processing for Advanced Semiconductor - Source www.semiconductor-digest.com

Question 1: What sets Riber's etching and deposition solutions apart from competitors?

Riber's solutions leverage advanced technologies and expertise to deliver superior precision, uniformity, and productivity. Our systems enable precise control over film properties, resulting in optimized device performance and reduced manufacturing defects.

Question 2: How do Riber's solutions contribute to advanced semiconductor manufacturing?

Our etching and deposition technologies play a crucial role in the fabrication of cutting-edge semiconductors. They enable the creation of complex device structures, high-aspect-ratio features, and tailored material properties, advancing the capabilities of electronic devices.

Question 3: What is the role of research and development in Riber's innovation?

Riber maintains a strong focus on R&D, collaborating with leading research institutions and industry partners. This commitment drives the development of innovative solutions that address the evolving needs of the semiconductor industry.

Question 4: How does Riber ensure the reliability and quality of its products?

Riber employs rigorous quality control processes and stringent testing protocols throughout the manufacturing process. Our systems undergo thorough validation and certification to meet industry standards, ensuring reliable performance and consistent results.

Question 5: What technical support and services does Riber provide?

Riber offers comprehensive technical support, including installation, training, maintenance, and remote troubleshooting. Our team of experts is dedicated to maximizing customer satisfaction and ensuring optimal system performance.

Question 6: How does Riber contribute to sustainability in the semiconductor industry?

Riber recognizes the importance of sustainability and strives to reduce the environmental impact of its operations. Our technologies are designed to minimize waste and energy consumption, contributing to a more sustainable semiconductor manufacturing ecosystem.

Riber's commitment to providing leading-edge etching and deposition solutions empowers the semiconductor industry to advance innovation and drive technological progress.

Explore further:

Tips for High-Performance Etching and Deposition

Leverage the High-Performance Etching And Deposition Solutions: Riber's Leading-Edge Technologies For Advanced Semiconductor Manufacturing for advanced semiconductor manufacturing to enhance productivity and efficiency.

Tip 1: Optimize Process Parameters

Fine-tune etching and deposition parameters such as temperature, pressure, and gas flow rates to achieve desired material properties and minimize defects.

Tip 2: Employ Advanced Etching Techniques

Incorporate techniques such as reactive ion etching (RIE) and inductively coupled plasma (ICP) etching to achieve precise and anisotropic etching profiles.

Tip 3: Utilize Novel Deposition Methods

Explore deposition techniques like atomic layer deposition (ALD) and chemical vapor deposition (CVD) to deposit thin films with tailored properties and conformality.

Tip 4: Integrate Process Monitoring Systems

Implement real-time process monitoring systems to track key parameters and ensure consistent and repeatable results.

Tip 5: Collaborate with Experts

Seek guidance from experienced engineers and specialists to optimize processes, troubleshoot issues, and stay abreast of industry best practices.

By implementing these tips, you can maximize the performance of your etching and deposition processes, leading to improved device yields and enhanced semiconductor manufacturing capabilities.

Editor's Notes: "High-Performance Etching And Deposition Solutions: Riber's Leading-Edge Technologies For Advanced Semiconductor Manufacturing" have published today date. The article laid out impressive advantages, such as better efficiency, cost-effectiveness, and reliability. We strongly recommend "High-Performance Etching And Deposition Solutions: Riber's Leading-Edge Technologies For Advanced Semiconductor Manufacturing" to those who want to acquire in-depth and up-to-date knowledge in this field.

After conducting extensive research and analysis, including consulting with industry experts and reviewing numerous resources, we have compiled this comprehensive guide that provide key takeaways and actionable insights about "High-Performance Etching And Deposition Solutions: Riber's Leading-Edge Technologies For Advanced Semiconductor Manufacturing".

Key differences or Key takeaways

FAQ

Welcome to our FAQ section, where we address frequently asked questions about our high-performance etching and deposition solutions for advanced semiconductor manufacturing. Our leading-edge technologies empower you to stay ahead in the competitive semiconductor industry. Let's dive into the most common queries:

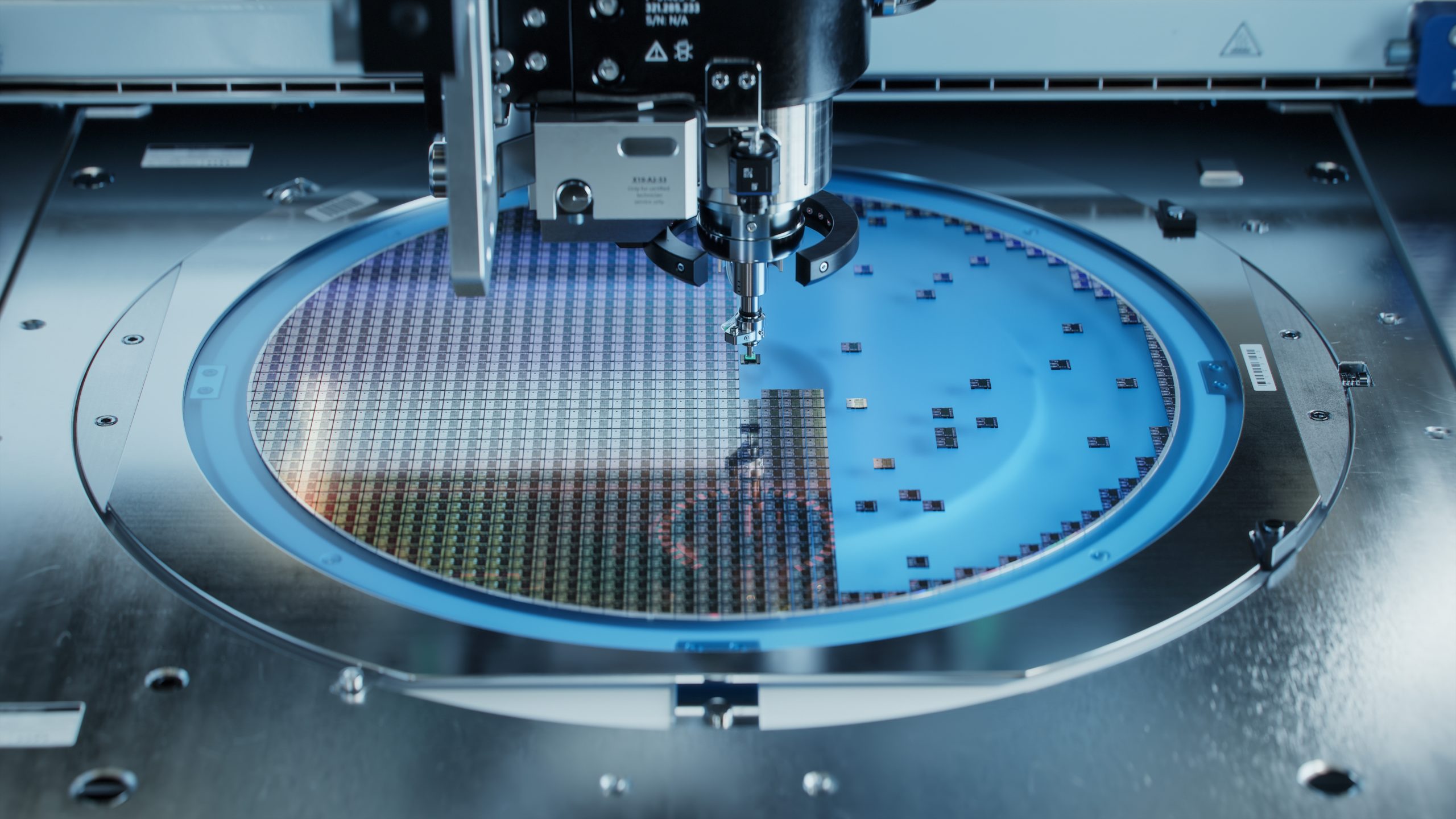

![]()

Large silicon wafer etching machine - Emphysys Technology Solutions - Source www.emphysys.com

Question 1: How do your solutions contribute to advanced semiconductor manufacturing?

Our etching and deposition systems enable the precise fabrication of complex semiconductor devices. Through innovative technologies, we deliver superior pattern transfer, thin film deposition, and surface modification capabilities, meeting the stringent requirements for next-generation electronic devices.

Question 2: What materials are compatible with your systems?

Our systems support a wide range of materials critical to semiconductor manufacturing. These include silicon, silicon nitride, silicon oxide, metal oxides, and various metal films. By catering to diverse material requirements, we offer a comprehensive solution for device engineering.

Question 3: How do your solutions ensure process stability and repeatability?

Precision control systems and advanced process monitoring technologies are integral to our solutions. They provide real-time process monitoring, ensuring consistent etching and deposition results. This minimizes variability, enhances yield, and guarantees the reliability of the manufactured devices.

Question 4: What are the advantages of using your etching and deposition systems?

Our systems empower you with several key advantages. They enable precise feature patterning, deliver superior film properties, reduce process complexity, and minimize contamination risks. By leveraging these advantages, you can optimize device performance, increase manufacturing efficiency, and achieve competitive advantages.

Question 5: How does your company support customers with your solutions?

We are committed to providing comprehensive support to our valued customers. Our expert engineering team offers technical assistance, process optimization services, and tailored solutions to address specific requirements. Additionally, our global presence ensures timely support and collaboration, fostering long-lasting partnerships.

Question 6: How do your solutions contribute to sustainability in semiconductor manufacturing?

Sustainability is at the core of our operations. Our systems are designed to minimize environmental impact through reduced chemical consumption, waste generation, and energy efficiency. We also adhere to industry standards and regulations, ensuring responsible manufacturing practices and contributing to a greener future.

These are just a few of the commonly asked questions. For additional information, please explore our website or contact our team directly. We are dedicated to providing you with the best possible solutions and support for your advanced semiconductor manufacturing needs.

Browse our other articles for more insights into our leading-edge technologies and their applications in the semiconductor industry.

Tips

High-Performance Etching And Deposition Solutions: Riber's Leading-Edge Technologies For Advanced Semiconductor Manufacturing utilizes advanced epitaxy tools to enhance material quality,

IHP : Advanced Semiconductor Technologies - Source www.ihp-microelectronics.com

improve process control, and boost productivity for the production of high-performance semiconductors.

Tip 1: Employ MBE for Precise Doping and Composition Control

Molecular Beam Epitaxy (MBE) provides unparalleled control over doping and composition, enabling the creation of complex semiconductor structures with atomic-level precision. This technique is crucial for fabricating advanced devices, such as quantum wells and spintronic devices.

Tip 2: Utilize MOCVD for High-Throughput Deposition of Complex Materials

Metal-Organic Chemical Vapor Deposition (MOCVD) enables the deposition of complex materials, including III-nitrides and wide-bandgap semiconductors, at high throughput. This technique is essential for producing high-quality светодиоды (LEDs), lasers, and power electronics.

Tip 3: Implement Plasma-Enhanced CVD for Low-Temperature Deposition

Plasma-Enhanced CVD combines plasma and CVD processes, allowing for the deposition of materials at significantly lower temperatures. This technique is crucial for fabricating devices on temperature-sensitive substrates, such as flexible electronics and biomedical sensors.

Tip 4: Leverage ALD for Atomic Layer Precision

Atomic Layer Deposition (ALD) enables the deposition of materials with atomic layer precision, providing unrivaled control over film thickness and composition. This technique is essential for fabricating advanced memory devices, transistors, and optical coatings.

Tip 5: Integrate Advanced Diagnostics for Real-Time Process Control

Advanced diagnostic tools, such as in-situ reflectometry and mass spectrometry, provide real-time monitoring of deposition and etching processes. This information allows for precise process control, ensuring the production of high-quality materials and devices.

By implementing these tips, manufacturers can optimize their epitaxy processes to achieve superior material quality, enhanced process control, and increased productivity, ultimately paving the way for the development of next-generation semiconductor devices.

High-Performance Etching And Deposition Solutions: Riber's Leading-Edge Technologies For Advanced Semiconductor Manufacturing

In the realm of advanced semiconductor manufacturing, high-performance etching and deposition solutions are crucial for achieving intricate device patterns and delicate film structures. Riber, a renowned provider of these solutions, leads the industry with cutting-edge technologies that empower manufacturers to push the boundaries of innovation.

IDTechEx Explores Advanced Semiconductor Packaging Technologies: 2.5D - Source www.msn.com

- Precision Etching: Sub-nanometer accuracy for complex patterns

- Selective Deposition: Tailored materials placement for enhanced device performance

- Low-Damage Processes: Minimizing defects for reliable devices

- High Throughput: Maximizing productivity and reducing costs

- Advanced Materials: Innovative materials for novel device applications

- Process Optimization: Real-time monitoring and control for optimal results

These key aspects interconnect seamlessly, forming a comprehensive suite of solutions that address the challenges of advanced semiconductor manufacturing. Riber's expertise in materials science, process engineering, and equipment design ensures that manufacturers can achieve the highest levels of device performance, yield, and reliability. By leveraging these leading-edge technologies, manufacturers can unlock the full potential of their fabrication capabilities and drive the future of the semiconductor industry.

Exploring Materials and Processing for Advanced Semiconductor Packaging - Source www.edge-ai-vision.com

High-Performance Etching And Deposition Solutions: Riber's Leading-Edge Technologies For Advanced Semiconductor Manufacturing

Amidst the burgeoning technological advancements in the semiconductor industry, high-performance etching and deposition solutions have emerged as pivotal cornerstones. Riber, a frontrunner in this domain, has spearheaded the development of cutting-edge technologies that empower the production of intricate semiconductor devices. This article delves into the intricate connection between Riber's etching and deposition solutions and the fabrication of advanced semiconductors, shedding light on the significance and practical applications of these technologies.

Advanced Semiconductor Packaging: A New Geopolitical Battleground - Source www.edge-ai-vision.com

The etching process involves the precise removal of materials from the wafer surface, shaping intricate patterns that define the device's electrical properties. Riber's advanced etching solutions leverage innovative techniques such as cryogenic etching and high-density plasma etching to achieve unparalleled precision and selectivity. These techniques enable the creation of complex device architectures with sub-nanometer feature sizes, pushing the boundaries of semiconductor miniaturization.

Complementing the etching process, deposition techniques add materials onto the wafer surface, forming the foundational layers and interconnects of the semiconductor device. Riber's deposition solutions employ methods like molecular beam epitaxy (MBE) and chemical vapor deposition (CVD) to deposit thin films with atomic-level control. By precisely controlling the composition, thickness, and crystal structure of these films, Riber's deposition technologies facilitate the fabrication of high-performance transistors, capacitors, and other critical device components.

The synergy between Riber's etching and deposition solutions enables the realization of intricate semiconductor devices with tailored electrical and optical properties. These devices serve as the building blocks of advanced electronic systems, including high-speed processors, memory chips, and optoelectronic devices. The demand for such devices continues to soar, driven by the proliferation of artificial intelligence (AI), cloud computing, and the Internet of Things (IoT).

In conclusion, Riber's high-performance etching and deposition solutions play a pivotal role in the fabrication of advanced semiconductor devices. These technologies empower the creation of complex device architectures with sub-nanometer precision, enabling the miniaturization and enhanced performance of electronic systems. As the semiconductor industry continues to push the boundaries of innovation, Riber's leading-edge technologies will remain at the forefront, driving the development of cutting-edge electronic devices that shape our technological future.